Preface for Golden Host Resort

Golden host resort is located between the airport and downtown Sarasota, has an outdoor pool and standard amenities, including a room with personal patios and balconies. This hotel is a 3-star hotel, but it looks beyond that level because more than 80 rooms have been renovated modernly since Nov 2020. With the long history of that hotel, people who lived in Florida were accustomed to staying here, especially for company activity and family gatherings. It’s worth it for you to go to that place to enjoy your exemplary life.

This article will share the updated bedroom furniture for you, and you will get a new impression after you look through the entire essay.

First, let’s see the 3D rendering photos for this mysterious hotel outside.

Second, let’s move your eyes to another area, the hotel room area; you will see the latest modern room designs and love it. –Inside View

Material for the Updated Hotel Room Furniture

The base material was made of E1 grade plywood, a material manufactured from thin layers or “plies” of wood veneer that are glued together with adjacent layers having their wood grain rotated up to 90 degrees one another. It is an enginaged wood from the family of manufactured boards which include Middle Density Fiberboard (MDF), oriented strand board (OSB) and particle board (chipboard). For more details, please check the web at google.com. That material is always used in 4-5 star hotel furniture, such as Hilton, Sheraton, Marriott hotel etc.

The surface for this furniture was HPL–(High-Pressure Laminate) finish. It is considered one of the most durable decorative surface materials and is available with unique performance properties, including chemical, fire and wear resistance. Unique grades of HPL can be post-formed around curved edges by heat and restraint. HPL is prevalent use in the USA, especially for Boutique-hotels.

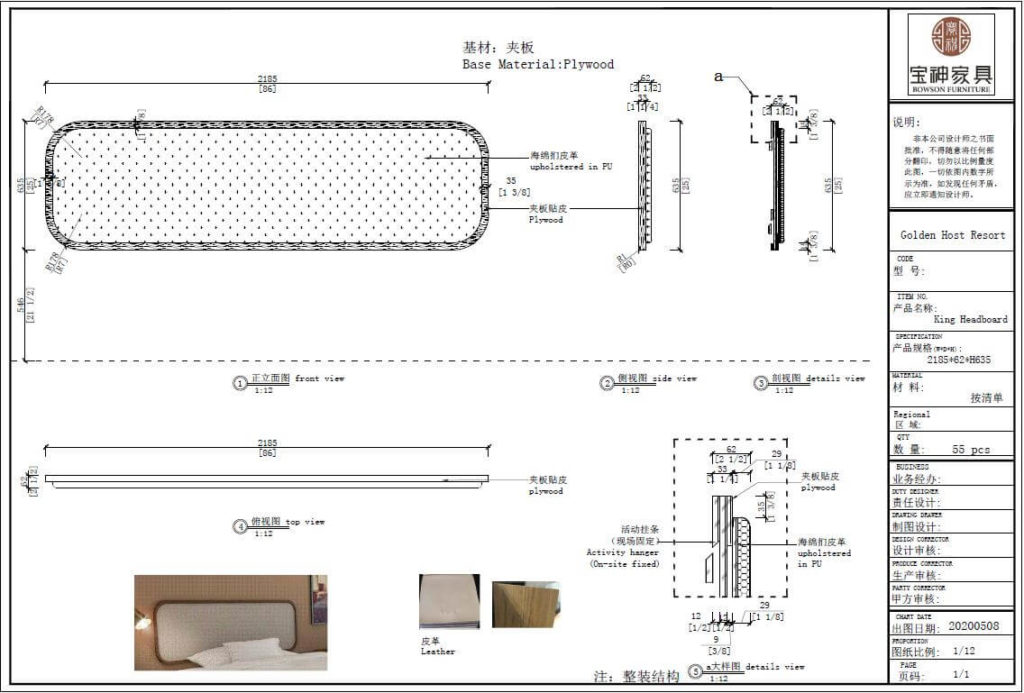

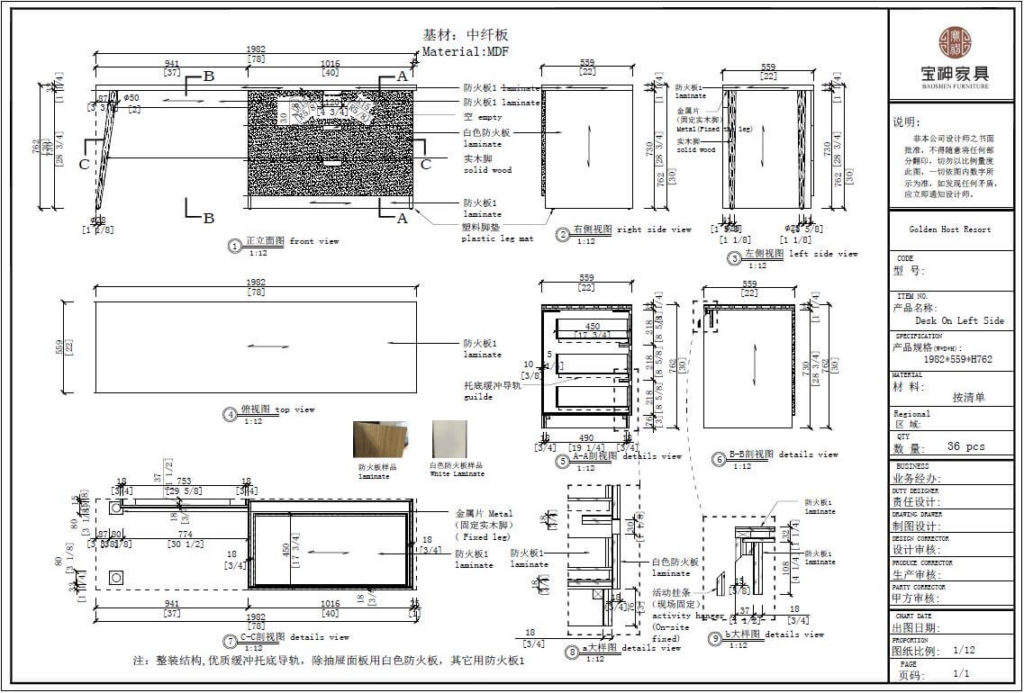

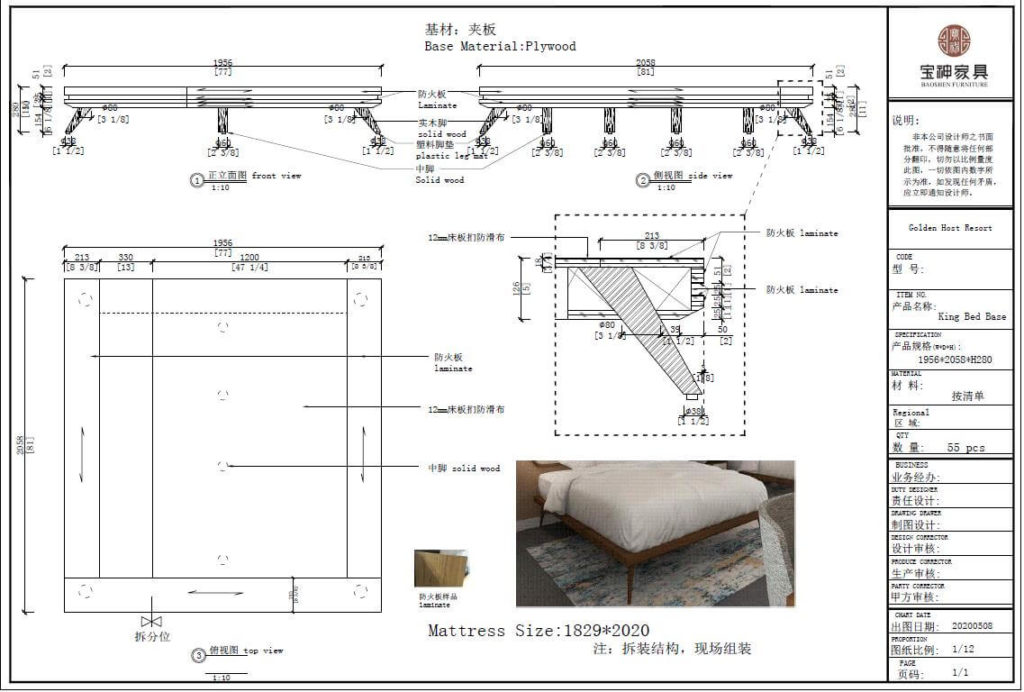

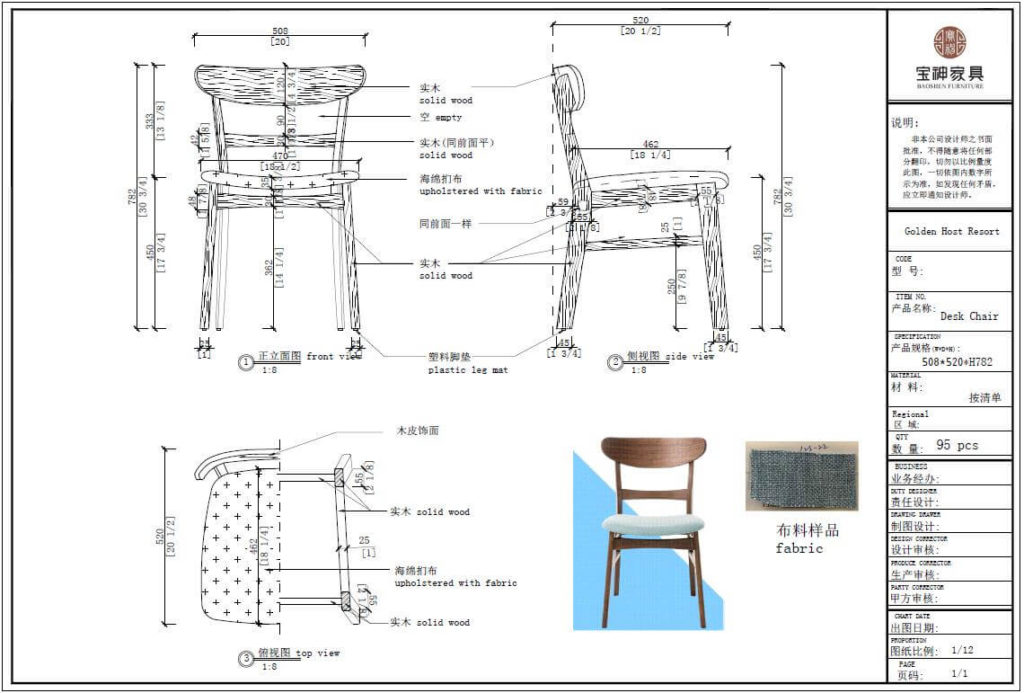

Golden Host Resort Furniture Manufacturing Drawings

Before manufacturing the Golden host resort furniture, we need to confirm the drawings, and it’s a significant step for making all kinds of bespoke furniture. Below are some shop drawings; you can have a look.

Furniture in the Production Workshop

The manufacturing step of this furniture is not difficult,

1. Prepare the raw material(Plywood and HPL)

2. Cutting the board by CNC automatic cutting machine

3. Drill the holes and edging banding

4. Assemble the furniture

5. Quality control and then packing.

The below photos are just for you as reference.

Finished Products Ready to Pack

After all production steps are accomplished, all the commercial furniture will be tested to avoid the manufacturing defects, and then go to the final step, the packing. Here are some furniture items for this hotel at the workshop.

For the packing, Bowson has the very strict stipulation that all the cartons have to be subject to the international export standard, and all corners must make complete protection to guarantee all goods do not accessible getting damaged on the container.

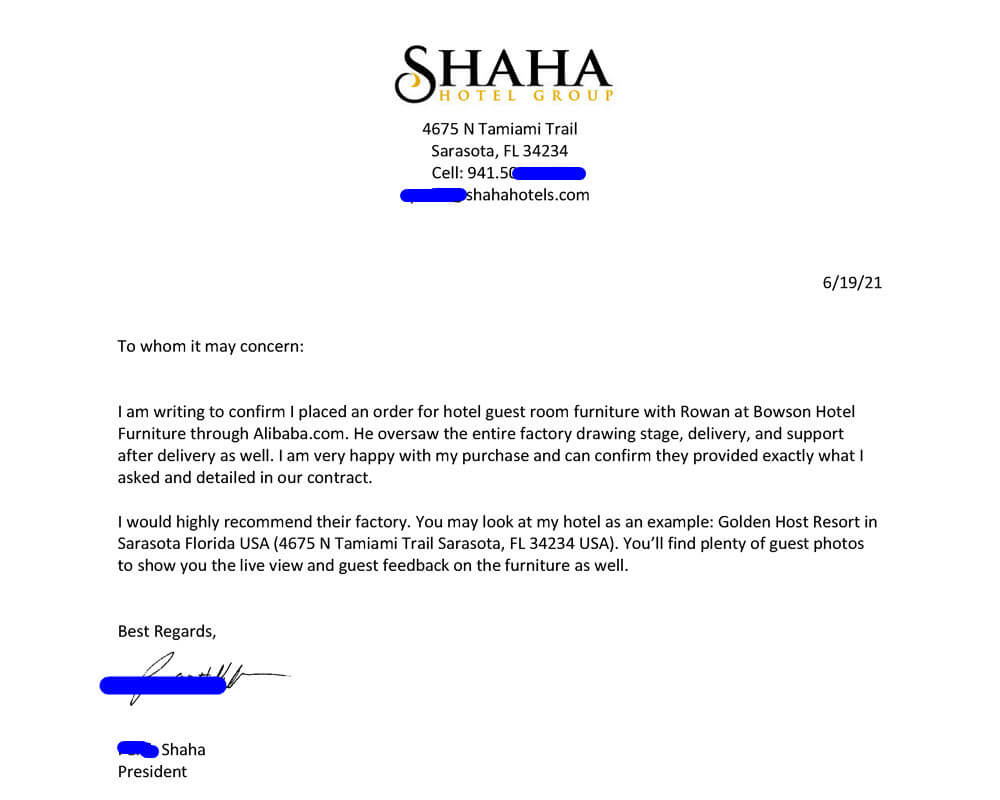

A few months later, the client has installed all hotel room furniture and is satisfactory for our product quality and after-sale service. We’re delighted to receive the letterhead from this hotel president.

Last but no least, all the hotel booking platforms are open; welcome to place this hotel guest room order online, and also you can visit the official website to get more details about it @ Golden Host Resort

Welcome to follow our official facebook @ bowson hotel furniture, and youtube channel @ bowson hotel furniture company, and also below were our original posts, please take a look.

- 2023 HOT WAY! Do You Know How to Repair Veneer Furniture?

- What is the Hotel Headboard, and How to Install it?

- Standard Materials in Furniture- Complete Guide for Hotels

- The Chinese Gate is Opening Soon. Are you ready to buy hotel furniture From China?

- Modern Qatar Hotel Furniture Project in the World Cup 2022